Cable drive the drive wheels of vehicles

1. Company

The company "Cable." — private property.

Witnessed in the Interdistrict IFTS of Russia No. 46 for Moscow — 20.08.2013

The address of the company: Russian Federation, 115598, g. Moscow, ul Zagor, D. 14, KOR. 1, room 105.

The owner of the business Borovskikh Valeriy Mikhailovich, owned share 100%.

At present the patents to the device, made a working prototype of a motorcycle in the manufacturing stage prototype of a Bicycle.

The project team

• Bohr, M. V. – developer and organizer of the project. Author of patents in the rope drives. The organizer prototype on a cable drive for a motorcycle. Engineer – avtostroitel, experience 45 years

• Levdansky A. V. — Commercialization, advertising, electronic interaction. Engineer, mathematician, experience 25 years.

• Yurtaev V. V. – development Director. Mechanical engineer, experience 10 years

• Anan'ev O. A. – the innovator has successfully completed a number of innovative projects, mentor of the year. The project will organize promotion of the project through the stages of development of the business model.

• It is planned to involve in the project implementation: at the first stage, the accountant and the designer; at the creation stage of production: the basic structural unit of the engineering enterprise.

2. Business idea, product

• DECIDE THE OBJECTIVE TO REDUCE FUEL CONSUMPTION IN TRANSPORT

• The solution – the application of ropes of a material such as "Kevlar", the Russian equivalent of "Armos" and "Rusar" in which prochnosti — weight characteristics tensile 24 times higher than structural steel. Previously, such materials were not used for torque transmission to the drive wheels of vehicles.

• Design is protected by four Russian patents, three of which are nationalized in Germany and one in USA.

The expected effect of reducing fuel consumption by 5% without increasing cost and weight reduction of automotive powertrain by 30 – 50 kg.

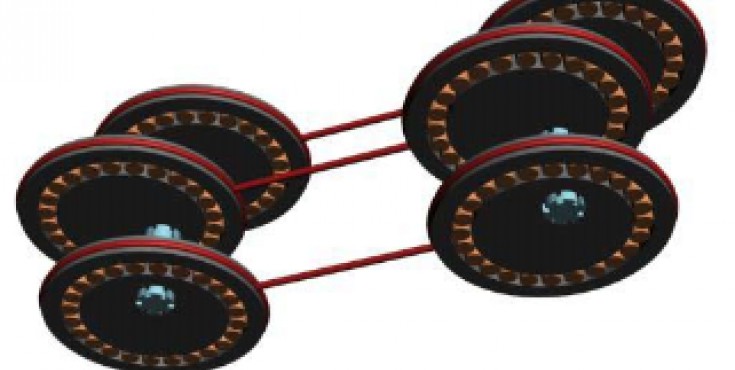

The comparison devices of the torque transmission

Left cable, right traditional drive to the second drive axle from the transmission of the vehicle with a transversely mounted powertrain. The diameters of the driven gears of the main gear are equal. The use of cable drive will reduce the weight of the actuator of the second bridge at 30 — 50 kg.

Prochnosti-weight characteristics of Kevlar above the steel rod in twenty four times

Currently no direct competitors, the cable drive no releases. But if to proceed with the development and entry into global markets of cable drives, competitors can appear. Countries such as Germany and the United States almost do not buy a license for production of devices and bypass the pioneer patents with a developed system of patenting.

The advantage of rope drives compared to traditional drives in the reduction of powertrain weight through strength aramid fibers such as "Kevlar" and fuel economy by eliminating transmission of two hypoid gears.

Created a workable prototype of a motorcycle. Required at its base to create a prototype for the certification test. You need to create prototypes of car and bike.

3. Market

The project operates on the old, the Mature market, the sales system honed over 100 years. It is planned to keep the competitive advantage of advanced development.

Market potential of Russia is one million four-wheel-drive cars and 500 thousand motorcycles and bicycles per year.

The global annual market potential of 20 million cars, 70 million motorcycles and 100 million bicycles

Customers: customers of the transport with the cable drives, the company buying licenses to the cable drive and do drive for installation on integrated transport, the customers of the projects on the drive.

The price set by the market. Assume the use of Russian components for the optimal price.

Sales yet

Similar products in the world yet.

For the entrance and development of traditional markets automobiles, motorcycles and bicycles.

Want to use traditional tools and channels for market entry.

The product will be sold for economic reasons.

4. The stages of the project

2016

Completion of a prototype motorcycle, development and production of a prototype car. Rope drive to make the involved enterprises. Car, motorcycle — purchase the vehicle. Cables of aramid fiber, bearings — purchased products.

Testing.

2017

Development of prototypes of automobile and motorcycle and finalization of the designs according to test results. Production of details on the involved enterprises.

Manufacturer of cable drives for prototype samples.

Certification of the developed modes of transport.

2018

The issue of transport equipment for 25 PCs each.

Delivery vehicles in commercial operation in the Russian army.

According to test results in operation to enlist the support of strategic investors.

To organize small-scale production, making maximum use of existing base components except perechisleny types of transport, ATVs, ATV amphibian and electric transport with rope drives (the volume of financial investments in facility and equipment up to one million dollars

2020

The newly organized enterprise of small batch production, the products, exploring the export possibilities of the developed transport.

5. Finance

To date, the company is funded from personal, very limited, funds. Just spent about $ 20,000. (Patenting of nationalization in Germany and the USA prototype fabrication).

Potential income from one drive to the car 210S, motorcycle 41S

Mass production of cable drives for manufacturers of transport equipment can be a very profitable business provided its early development. For the organization of production will require one million dollars.

A small company can mass-produce motorcycles, ATVs and bugs.

The full cycle can cost $ 10 million. Subject to export components, the enterprise can cost 1 million. dollars.

To run the project you must:

To produce a prototype car and to Refine the prototype motorcycle. For prototyping in the first phase will require 40 thousand dollars.

Create pre-production samples and certification will require 68 thousand dollars.

When creating prototypes and pilot models, you will need to place orders for the enterprise engaged in metal cutting and heat treatment (preferably automotive but not required) and the company producing belts or tires, for the manufacture of protected cables with pre-tension in the curing process.

In order to not only import substitution, but also on the issue of transport equipment for export, it is necessary to organize the production of four-wheel drive amphibious. The use of cable drives in such a car, will simplify construction and reduce weight. To date, available all-wheel-drive amphibious neither we nor abroad. This technique will find demand in Russia and abroad among hunters, fishermen, forestry and water management, during the development of the tundra and in the army.

The investor finances the further development of the project. It is necessary to Finance the creation of prototypes, product certification, the establishment of production and operations.

The authorized capital of LLC "Cable" -18000 rubles.

Intangible investment: patents and doing business.

Cost of goods pledged is equal to the traditional transmissions, it will actually be lower in case of realization of the submitted applications is much lower.

The investor is offered: when investing in the creation of prototypes of automobile and motorcycle 25% increased project cost; when investing in pre-series samples and the certification of 50% of the increased value of the company; investing in the production of cable drives and cable transport drives 80% of the value of the company.

An exit strategy from the company to the investor (buyout of an owner selling to another investor, sale to another company.

The company's mission is to increase exports of industrial products from Russia on the world market.

6. Risks

1. Greatly complicated by the interaction with the manufacturers, because a non-Russian origin of parent companies we have producing cars and delivering component parts of motorcycles. At Oise while seventy modernize the classic design.

2. The main risk is psychological, one of these actuators does not.

Key success factors:

1. The project offers an improved technique.

2. The project operates on the old current market.

3. The project is technologically simple and allows you to immediately jump to the export.

Additional information

Russia, Moscow oblast, Moscow

Project price: 960 000 000

Investments volume: 800 000 000

Stage: Project is at development stage

2526 reviews

Borovskikh Valeriy Mikhaylovich