SUMMARY

the project "Integrated development improve the efficiency

coal mines, due to pre-demethanization of coal

layers and disposal of methane, with the production of it

feed protein and microbial autolysis way."

Moscow 2017.

1.The relevance of the topic.

Despite the great work done by the coal companies to improve the safety of miners, periodically have the scene of the accident with fires and methane explosions with severe consequences.

Coal mines in Russia emitted billions of cubic meters of methane. The methane content of one of the mine reaches 20 million m3 per year.

Methane as a carbon source and hydrogen can be wonderful raw materials for the production of proteins, particularly feed proteins (gapena).

In 80-e years in the USSR, on the instructions of the USSR Ministry of coal industry, Ministry of education, Gosstroy, the state planning Commission and state science and technology Committee was developed and tested by microbiological method for the production of biomass from methane in coal mines.

Obtained more than 10 patents for this invention. Conclusion of Ministry of health of USSR for application in the production of Caprine

feed is available.

Further development of this method is connected with the beginning of privatization and was discontinued for two main reasons:

1.1.Production of feed protein from methane natural gas in the Boichemical Svetloyarskiy, Volgograd region, was discontinued in 1991 due to unprofitability, since the use of purchased natural gas is significantly (approx 40%) increased the cost of production. Only the plant produced about 10,000 tons caprina.

1.2.Microbiological test method in the coal mines of Donbass to reduce the concentration of methane in the underground tunnels and dead ends were terminated in 1992 in connection with the privatization of coal mines.

2. The purpose of the project.

2.1.Improving the productivity of the miners, due to the demethanization of coal seams prior to coal mining.

2.2.The almost complete exclusion of the possibility of occurrence of explosive concentrations of methane in the mine and waste sites of coal mines.

2.3.Disposal captainoppa methane producing feed protein (Caprine) autolysis (patent, OOO "General, econef" No. 2571853).

3.Research and development

3.1.Verification in the laboratory of quality feed protein (Caprine) and its autolysis of coal mine methane.

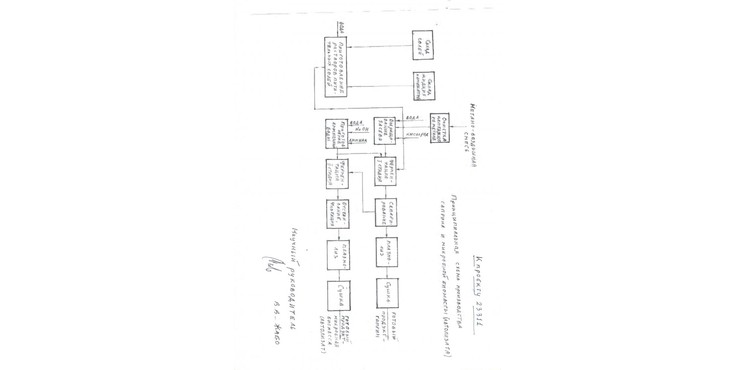

3.2.Elaboration of optimal schemes of borehole entry of a suspension of microbial mass in the coal seams and surface of its application in waste areas.

3.3.The creation of experimental-industrial installations for the production and use of Caprine and autolysis in a coal mine.

3.4.Analysis of changes of the microclimate in different parts of the coal mine after the implementation of the microbiological method.

3.5.Conducting industrial research on agricultural animals and fish use efficiency caprina and its autolysis of feed.

3.5.Marketing research.

4.Economic indicators

4.1.The expected productivity growth – 15 - 20%.

4.2.Research and development — 60 million rubles.

4.3.Project documentation development (testing set and head for the selected coal mine — 50 million.

4.4.Design and manufacture of custom

Equipment 325 million.

4.5.The purchase of standard equipment — 65 million rubles.

4.6.Instruments and measuring equipment — 25 mln rubles.

4.7.Construction work of the head of the complex — 50 million.

4.8.Commissioning — 15 million rubles.

4.9.Emergency work 9, 5 million.

TOTAL: 599, 5 million.

The expected selling price of dry commercial caprina – 35 RUB/kg

Also autolysis — 45 RUB/kg

With an average methane content of coal mines of 15 million m3/year will be produced 5000 t caprina. 50% caprina will be spent on the production of autolysis.

Sales caprina: 5000-2500= 2500 t/year.

Sales of products: caprina 2500*35*103=87500000, 0, RUB/year .

Autolysis 2500*45*103=112 500 000, 0, RUB/year .

All sales of products — 200 mln. rubles/year.

Given the increase of coal production by 15-20%, the payback will be no more than 3x years.

Allancastria

Company website

Market analytics

The deficit of feed protein in Russia is not less than 1 million tons per year

This is a brand new technology at the intersection of mining Sciences, Microbiology, energy and fodder production

1.In the project feed protein is produced from emissions of methane. 1 kg caprina in which 70% of protein will cost about 35 RUB.

2. From kaprina the new technology will be autolysis. While the efficiency of its absorption from farm animals, birds, fish increases 4, 5 — 5 times.

Russia, Kemerovo Oblast, Novokuznetsk

Project price: 599 500 000

Investments volume: 599 500 000

Stage: Project is at development stage

Website: atpmsk.ru

479 reviews

Zhabo Vladimir Vladimirovich