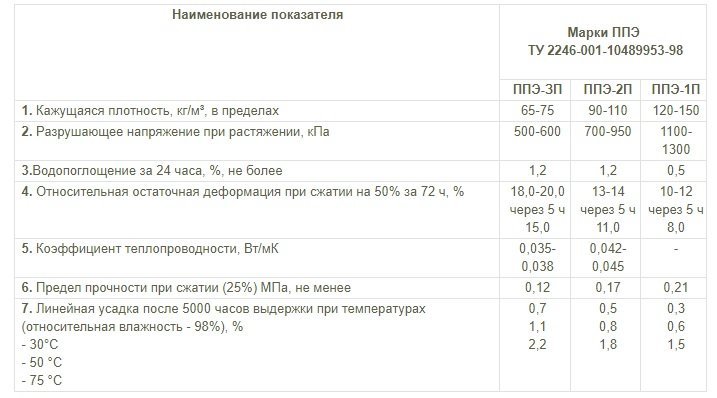

Hello, my name is Anatoly. I have higher education on a speciality Pererabotka plastics and elastomers. Currently working and involved in the development and creation of new formulations spennende materials. Developed different formulations of foamed polyethylene on the basis of different fields of application. Rassmotrim more properties of the foam, its advantage over other materials and applications. Polyethylene foam is a relatively new but already well-proven material in many applications. Due to its unique properties, such as Durability and abrasion resistance — Environmental safety — water Resistance — Resistance to deformationally, elasticity and progolosoval sheet is a polymer foam in the production process to fine polystyrene structure. Soft and supple, warm to the touch material has become the insulation of the new generation, exceeding its insulation properties most of the traditional thermal insulation materials.Development and selection of formulations to foam was conducted on a special laboratory equipment. Was obtained and tested the following brands of penopolietilena.The test results of polyethylene foam in accordance with the technical specifications: applications cross-linked polyethylene foampolyethylene Foam stamps TPP-1P — engineering: — universal packaging for devices and equipmento - — - striptermo noise isolation salonsFoam stamps TPP-2H, TPP-3P. — Sport, recreation, tourism: — tourist mats in various sizes and modifications — protective pads and helmets for active sports — swimming boards, raftsa Particular advantage of the foams from other materials in that the material lends itself well to shaping and fully recovers its size after removing the load.For the production of polyethylene requires special industrial equipment

applications cross-linked polyethylene foampolyethylene Foam stamps TPP-1P — engineering: — universal packaging for devices and equipmento - — - striptermo noise isolation salonsFoam stamps TPP-2H, TPP-3P. — Sport, recreation, tourism: — tourist mats in various sizes and modifications — protective pads and helmets for active sports — swimming boards, raftsa Particular advantage of the foams from other materials in that the material lends itself well to shaping and fully recovers its size after removing the load.For the production of polyethylene requires special industrial equipment

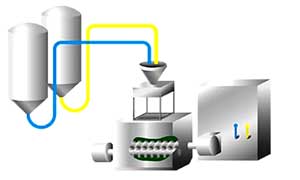

Principal technological scheme of production of sheet foam.

1. Weighing and batching components, preparation of the mixture for subsequent extrusionAt this stage prepared of pure components with high precision are mixed in the required compound. 2. Extrusion of sheet with the given parameters ofthe extrusion Process widely used surgery for the production of such products as pipes, profiles, sheets. In the extruder are one or two of the auger (screw) that rotates the heated material is extruded through an extrusion die (Spinneret), giving the product the desired shape.

2. Extrusion of sheet with the given parameters ofthe extrusion Process widely used surgery for the production of such products as pipes, profiles, sheets. In the extruder are one or two of the auger (screw) that rotates the heated material is extruded through an extrusion die (Spinneret), giving the product the desired shape. 3. Foaming under pressureafter the extruder, the material is trimmed and served in a stitching unit, after which is fed into a press where, under high temperature and pressure. From the ovens out the sheet of foam that is packaged and sold or undergoes further processing.

3. Foaming under pressureafter the extruder, the material is trimmed and served in a stitching unit, after which is fed into a press where, under high temperature and pressure. From the ovens out the sheet of foam that is packaged and sold or undergoes further processing.

Mixer is necessary for mixing of the main components of the future material :

Rolls for subsequent processing of polymeric materials, which consists in the repeated passage of raw materials through the gap between the heated metal rollers, making a rotational movement towards each other. The polymer becomes soft, mixed, and finally homogenized under the action of the deformation effort.

Rolls for subsequent processing of polymeric materials, which consists in the repeated passage of raw materials through the gap between the heated metal rollers, making a rotational movement towards each other. The polymer becomes soft, mixed, and finally homogenized under the action of the deformation effort. Roll forming machine used for molding of the sheet in the final product, setting a specific size and thickness.

Roll forming machine used for molding of the sheet in the final product, setting a specific size and thickness. The finished polymer sheet calibrated in width and thickness, sent to the furnace, where the chemical crosslinking due to the activation of the reagent-stapler, which begins to act only when exposed to high temperatures. After removing the pressure is already formed sheet of foam.

The finished polymer sheet calibrated in width and thickness, sent to the furnace, where the chemical crosslinking due to the activation of the reagent-stapler, which begins to act only when exposed to high temperatures. After removing the pressure is already formed sheet of foam. Dolina machine prednaznachena for cutting the finished product to a certain thickness

Dolina machine prednaznachena for cutting the finished product to a certain thickness .

.

Market analytics

The rate of growth in the world market of polyethylene ranging in average from 4 to 15%. Thus it can be seen that in developed countries like the US or Western Europe the growth rate is low – at level 3, 5-5%, on the contrary, in developing countries, which are currently undergoing the same phase that, for example, the United States passed 5-10 years ago, the growth rate can exceed 15%.

The largest consumer market can be called USA. The consumption of this country in 2005 is estimated at 96, 5 thousand tons, which is slightly more than half of the total volume of consumption of polyethylene in the world. The rest of the world far behind America. Thus, the total volume of demand of European countries reached the level of 45-50 thousand tons.

The world market for polyethylene foam products, is relatively new and is characterized by consolidation into large group of companies, allowing them to expand the proposed range of foamed products, thereby diversifying production capacity and to increase markets.

The specificity of the material allows us to export it long distances, which creates the need to build production close to markets.

Russia, Vladimir Oblast, Sudogda

Project price: 20 000 000

Investments volume: 20 000 000

Stage: Project is at development stage

364 reviews

Tesakov Anatoliy Aleksandrovich