| It is necessary to stretch a steel wire rod. Operations occur at the drawing machines. The basis are the rows of nozzles of different diameter. A metal rod that passes through them is reduced gradually in diameter. Appliances equipped with a cooling system. | |

| Stage 2 | Cut blanks to the required length. Shaping hats for cold heading machines. |

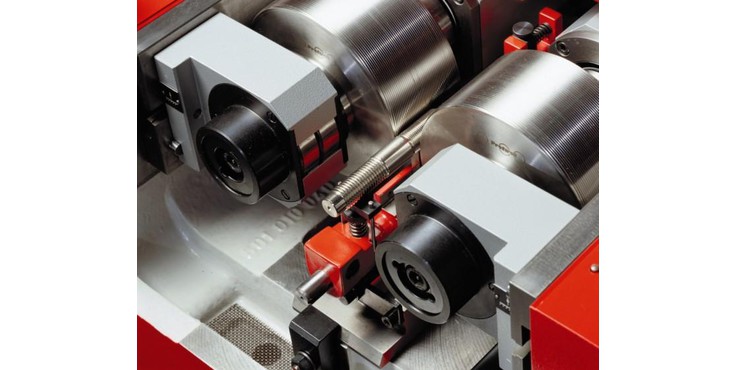

| Stage 3 | Is the transportation of the workpiece on installation for nakatok thread. It is necessary to use a special conveyor. They come with clamps for the workpiece. |

| Stage 4 | The product is delivered to the furnace, where annealing at a temperature of 930 degrees. After that, the temperature is progressively reduced. This must be done for a uniform lifting of the plane of tension of the metal. Further, the screw receives the line for washing. |

| 5 stage | It is necessary to apply a galvanic coating. Use a small amount of baths. Is the billet surfaces and the application of anticorrosion layers. In the final tub is mounted zinc anode. |

| Stage 6 | In a special centrifuge is dried. This is the penultimate stage of the industrial process. |

| 7 stage | The final step is quality control of the product and its packaging. |

Russia, Moscow Oblast

Project price: 1 000 000

Investments volume: 1 000 000

Stage: Idea

740 reviews

Titov Ivan Vladimirovich